You can boost your high-pressure fluid system’s efficiency. Finding and fixing hidden leaks is your first step. These leaks drain energy and fluid, increasing costs. For example, a single 1mm leak can cost over €180 annually. Selecting correctly sized components, like a suitable chemical pump, also prevents pressure drops and energy waste. Finally, you should implement a proactive maintenance schedule. This ensures your system performs at its best for a long time.

Identifying and Correcting Core Inefficiencies

Your system’s efficiency depends on finding and fixing problems. Many issues hide in plain sight. They quietly waste energy and increase your operating costs. You can take control by auditing your system, clearing restrictions, and managing heat. These steps will boost performance and save you money.

Conduct a System Audit to Pinpoint Leaks

Leaks are a primary source of energy waste. A single dripping faucet can waste over 3,000 gallons of water a year. In a high-pressure system, even a tiny leak has a big impact. It reduces pressure, wastes expensive fluid, and creates safety hazards. You must find and fix these leaks to run an efficient operation.

Some leaks are very hard to find. In systems running above 200 bar, micro-cracks can release fluid as a fine, invisible mist. This atomized fluid is a serious fire risk and a sign of developing component failure. Finding these small leaks early prevents major downtime and costly repairs.

Pro Tip: Use Advanced Tools for Leak Detection You can find hidden leaks with modern technology. These tools help you see and hear what the naked eye cannot.

Acoustic Imaging Cameras: These devices create a visual map of sound. They let you “see” the exact location of a high-pressure fluid or gas leak, even in a noisy factory.

Ultrasonic Sensors: These tools detect the high-frequency sound a leak produces. You can use them to pinpoint both external and internal leaks in components like valves and cylinders.

Black Light Dyes: You can add a special dye to your hydraulic fluid. When the fluid leaks, it will glow brightly under a black light, making even the smallest drips easy to spot.

Common causes of leaks often point to bigger problems. A thorough audit helps you identify these root causes.

|

Common Leak Causes |

Description |

| Fluid Contamination | Dirt, water, or metal particles wear down seals and damage components. |

| Component Wear | Seals, hoses, and gaskets naturally degrade from pressure and use. |

| Overheating | High temperatures damage seals and reduce the fluid’s protective ability. |

| Incorrect Installation | Misaligned parts or improper assembly puts extra stress on connections. |

| Pressure Spikes | Sudden pressure surges can damage hoses, fittings, and even pumps. |

Resolve Pressure Drops and Flow Restrictions

Every time fluid moves through a pipe, bend, or valve, it loses some pressure. This is called a pressure drop. While some pressure drop is normal, excessive drops force your pump to work harder. This wastes energy and reduces system performance. You can improve efficiency by creating a smoother path for your fluid.

Flow restrictions are the main cause of unnecessary pressure drops. You should check your system for these common issues:

Poor Inlet Design: Sharp bends or sudden pipe contractions near the pump inlet can starve the pump of fluid.

Undersized Hoses or Pipes: Lines that are too small for the flow rate create high resistance and friction.

Clogged Filters: Dirty suction strainers or filters block fluid flow and reduce inlet pressure.

Partially Open Valves: Gate valves are not designed for throttling flow. Using them partially open creates turbulence, noise, and major pressure loss.

You can design your system for smooth, efficient flow. Following best practices during installation and upgrades prevents future headaches. Make sure you select the right components for your application. Use gentle bends instead of sharp elbows. Ensure all pipes and hoses are properly sized and supported to avoid vibration. A well-designed layout gives your fluid a clear, unobstructed path, which minimizes pressure drops and maximizes efficiency.

Minimize Energy Loss from Heat Generation

Does your system run hot? Heat is a clear sign of inefficiency. When your system generates excessive heat, it is converting valuable energy into wasted thermal energy instead of useful work. This heat also degrades your hydraulic fluid, damages seals, and causes premature component failure.

Did You Know?The viscosity, or thickness, of your fluid is closely tied to temperature. As fluid gets hotter, its viscosity drops. While this can sometimes reduce flow resistance, excessive heat is harmful. It thins the fluid too much, reducing its ability to lubricate and protect vital components.

Managing heat starts with identifying its source. The most common causes of overheating are related to friction and restriction.

Excessive Fluid Friction: This occurs when fluid is forced through undersized hoses, dirty filters, or restrictive valves.

High Leakage or Slippage: Internal leaks in pumps or valves force fluid to bypass its intended path, generating heat without doing any work.

Overloading: Running your system beyond its designed pressure or capacity puts immense stress on components, creating excess friction.

Contamination: Dirt and debris in the fluid increase friction and can cause components to malfunction, leading to localized overheating.

A great way to manage system temperature is with a heat exchanger. These devices work like a radiator for your fluid system. They transfer heat away from the hydraulic fluid to another medium, like air or water. By installing a properly sized heat exchanger, you can maintain a stable operating temperature. This protects your fluid and components, prevents energy loss, and ensures your system runs at peak efficiency for years to come.

Optimizing Components and Maintenance for Peak Performance

Fixing existing problems is only half the battle. You can achieve true efficiency by choosing the right parts from the start and caring for them properly. Smart component selection and a solid maintenance plan work together. They prevent problems before they start, ensuring your system runs reliably for years. This approach saves money, improves safety, and boosts performance.

Select the Right Hoses and Tubing

The hoses and tubing in your system are like its arteries and veins. They carry fluid under immense pressure. Choosing the wrong type can lead to catastrophic failures, equipment damage, and serious safety risks. You must select lines that match your system’s pressure, temperature, and application.

Generally, you will choose between flexible hoses and rigid tubing. Each has a specific purpose.

|

Feature |

Flexible Hoses |

Rigid Tubing |

| Construction | Rubber or thermoplastic with fiber/steel reinforcement | Metal like steel or stainless steel |

| Flexibility | High; bends easily and absorbs vibration | Low; very strong and resists kinking |

| Best For | Dynamic parts (moving arms, mobile equipment) | Stationary systems (fixed industrial machinery) |

| Installation | Can be cut to size; uses crimped or threaded fittings | Requires precise bends; uses flared or welded connections |

Using the wrong size is a common and costly mistake.

Undersized Hoses: Lines that are too small restrict fluid flow. This creates friction, generates heat, and makes your pump work harder. Your system will feel sluggish and may not reach its peak performance.

Oversized Hoses: Lines that are too large can cause excessive pressure drops. This wastes energy and can slow down the response time of your equipment.

Always verify that your components are made from the right materials and can handle your system’s operating conditions. This includes pressure, temperature, and the type of fluid you are using.

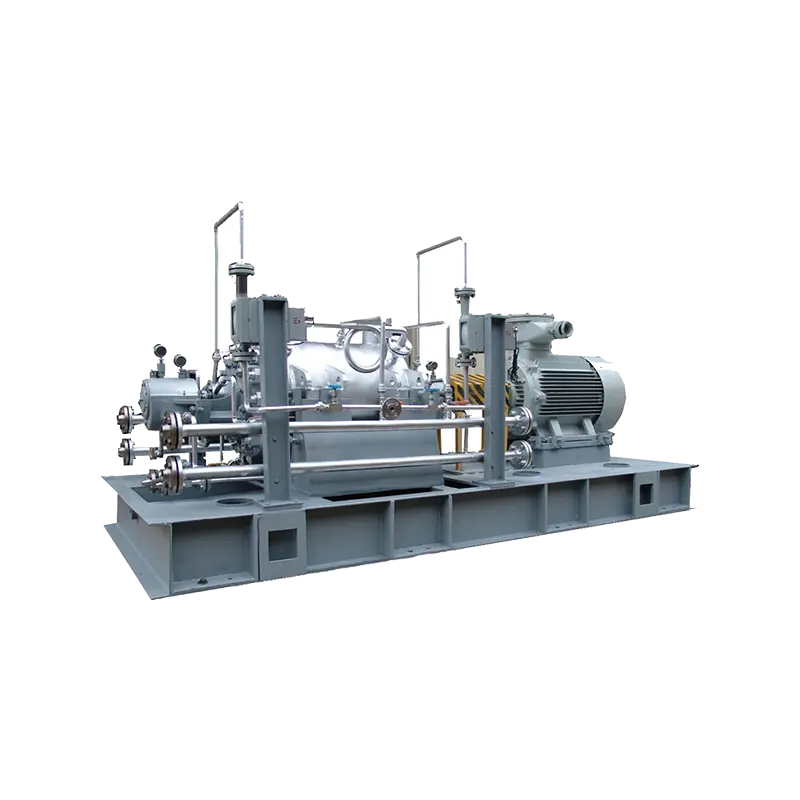

Match Your Chemical Pump to System Demands

The pump is the heart of your high-pressure system. Matching your chemical pump to your system’s needs is critical for efficiency and long life. An oversized pump wastes energy and can cause excessive wear. An undersized pump will struggle to meet demand and burn out quickly.

When selecting a chemical pump, you should focus on three key areas:

Flow Rate (Q) and Pressure (H): You need to know the volume of fluid your system requires (flow rate) and the total pressure the pump must overcome (head). Consider both average and peak demand. Choosing a chemical pump with the correct performance curve ensures it operates at its Best Efficiency Point (BEP), saving energy and reducing stress.

Material Compatibility: The pump’s materials must be compatible with the fluid you are moving. For clear water, cast iron may be fine. For corrosive chemicals or high-temperature fluids, you need a chemical pump built from robust materials like stainless steel, special alloys, or advanced polymers to prevent corrosion and ensure a long service life.

System Design: A well-designed system supports your pump. For demanding industrial jobs, you need a chemical pump built for reliability. For example, the SLDT SLDTD series is engineered to API610 standards for the oil and gas industry. These pumps handle extreme pressures up to 25MPa and temperatures from -80℃ to 180℃. Models like the SLDTD (BB5) use a forged, double-hull structure for exceptional stability in high-pressure environments.

Expert Tip: Prevent Pump Cavitation Cavitation is the formation and collapse of vapor bubbles inside a pump. It sounds like gravel is running through your system and can quickly destroy internal components. You can prevent it by:

Ensuring the pressure at the pump inlet (NPSHa) is always higher than what the pump requires (NPSHr).

Keeping fluid temperatures within the designed range.

Using properly sized pipes on the inlet side to avoid starving the pump.

Operating your chemical pump near its Best Efficiency Point (BEP).

A properly specified chemical pump is a reliable and efficient asset. The best units are also designed for easy maintenance. The SLDTD’s innovative sectional design allows you to remove the entire inner assembly for repairs without disconnecting the main pipelines, drastically cutting downtime.

Implement a Proactive Maintenance Schedule

The best way to fix a problem is to prevent it from happening. Proactive maintenance helps you find and correct small issues before they become major failures. This approach keeps your system running smoothly, reduces the risk of accidents, and makes your budget more predictable.

There are several types of proactive maintenance:

Preventive Maintenance (PM): Performing scheduled tasks like cleaning, lubrication, and filter changes at regular intervals.

Condition-Based Maintenance (CBM): Performing maintenance only when specific conditions are met, often tracked by sensors.

Predictive Maintenance (PdM): Using data from sensors to spot trends and forecast failures, allowing you to act just in time.

A strong maintenance plan starts with good habits. Keep detailed records of all repairs and scheduled work. Train your team to spot early warning signs like unusual noises, speed changes, or rising temperatures.

Here is a sample inspection schedule for common wear parts. You should adjust it based on your equipment’s usage and operating environment.

|

Component |

Recommended Inspection Frequency |

| Leaks | Weekly or Monthly |

| Hoses | Monthly |

| Seals | Every 3-6 Months |

| Filters | Monthly (Replace every 3-6 months or as needed) |

Modern technology can make your maintenance program even smarter. Tools like oil analysis, acoustic sensors, and thermal imaging help you understand the health of your equipment without taking it apart. For example, sending a fluid sample to a lab can reveal tiny metal particles, a sign of internal component wear. This gives you a chance to schedule a repair before a catastrophic failure occurs

Use Filtration to Protect System Integrity

Did you know that up to 80% of all hydraulic system failures are caused by contaminated fluid? Dirt, water, and even air bubbles can turn your fluid into a liquid sandpaper that erodes sensitive components. Contamination reduces efficiency, generates heat, and is a leading cause of leaks and breakdowns.

Filtration is your system’s only defense. A multi-layered filtration strategy removes harmful particles and protects your investment. Key filter locations include:

Reservoir Breather: Stops airborne dirt and moisture from entering the tank as the fluid level changes.

Suction Strainer: A coarse screen that protects the pump from large debris.

Pressure Filter: Placed after the pump to catch any particles generated by the pump itself.

Return Line Filter: Cleans the fluid as it returns to the tank, capturing wear particles from system components.

Understanding Fluid Cleanliness: The ISO 4406 Code The ISO 4406 cleanliness code is the industry standard for measuring fluid purity. It is a three-number code (e.g., 18/16/13) that tells you how many particles of different sizes are in a fluid sample.

The first number counts particles ≥4µm (fine particles that cause wear).

The second number counts particles ≥6µm (mid-sized particles that jam parts).

The third number counts particles ≥14µm (large particles that cause blockages).

Equipment manufacturers specify a target ISO code for their components. High-pressure systems with sensitive pumps and valves require much cleaner fluid (a lower ISO code) than simple systems. Meeting this target is essential for reliability.

By installing high-quality filters and changing them regularly, you keep your fluid clean. This protects your chemical pump, valves, and actuators from premature wear, ensuring your system operates with maximum efficiency and reliability.

Start with a system audit to find inefficiencies. You can achieve long-term reliability by optimizing components and using a proactive maintenance plan. This approach creates a safer workplace by reducing hazard exposure. It also delivers significant savings, cutting maintenance costs by up to 28% while improving overall system performance.

FAQ

How often should I check for leaks?

You should perform a quick visual check weekly. A more thorough audit using tools is best done monthly or quarterly, depending on your system’s use.

What is the first sign of a pressure drop?

Your equipment may feel sluggish or slow. You might also notice the pump running louder or longer than usual to keep up with demand.

Why is my system running hot?

Heat often means inefficiency. It can come from fluid friction, internal leaks, or running the system beyond its limits. It wastes energy and damages parts.

Post time: Nov-07-2025