Our company’s 5000 m³/d integrated modular water plant in Angola, contracted with DAJIANG CONSTRUCTION, LDA, has recently completed on-site commissioning, commenced operation, and achieved effluent quality standards. It has been handed over to the local water company for operation. This is another exemplary project of Liancheng products in Africa!

The successful implementation of the SPW integrated modular water plant project in Angola has ensured the safety of drinking water for local residents, greatly improved their quality of life, reduced the incidence of diseases caused by drinking unclean water, and protected public health. This project will become a model project in Angola’s infrastructure construction sector, providing valuable experience for subsequent water purification projects in other regions, and laying a solid foundation for the high-quality development of Liancheng products in overseas markets.

Part 01

Project Results Showcase

The SPW integrated modular water plant project in Angola is a significant achievement for Liancheng Group in the African market. With a capacity of 5,000 m³/d, the project integrates multiple advanced technologies to provide local residents with a safe and reliable source of drinking water.

The project has completed on-site commissioning, been put into operation, and achieved effluent quality standards, and has been officially handed over to the local water company for operation. This signifies that Liancheng Group’s technical strength and service capabilities in the overseas water market have been internationally recognized.

Part 02

Letter of thanks from partners

Our project partner, DAJIANG CONSTRUCTION, LDA, sent us a letter of appreciation, highly praising our professional technical capabilities and efficient implementation services.

Part 03

SPW Integrated Modular Water Plant Introduction

The SPW series integrated modular water plant is an intelligent water purification equipment (system) developed by Liancheng Group for municipal water supply, rural drinking water, and industrial park wastewater reuse. This equipment (system) integrates coagulation, sedimentation, filtration, and disinfection processes, and combines with various modular systems such as a water intake system, water quality monitoring system, intelligent dosing system, air-water backwashing system, video security system, intelligent control system, and intelligent water supply system to achieve intelligent linkage and coordinated operation of multiple systems.

The SPW series integrated modular water plant is based on standardized design, factory prefabrication, and rapid on-site modular assembly. It can be flexibly combined with IoT cloud platforms or AI computing power to achieve unmanned operation and remote maintenance, which is in line with the current development trend of intensive, green and intelligent water treatment industry.

Key technical features:

Standardized design, factory prefabrication, and rapid on-site modular assembly

It integrates coagulation, sedimentation, filtration, and disinfection processes.

Intelligent linkage and collaborative operation of multiple systems

It can be flexibly combined with IoT cloud platforms or AI computing power

Achieve unattended operation and remote maintenance

In line with the trend of intensive, green, and intelligent development in the water treatment industry

Part 04

Intelligent control systems and AI technology applications

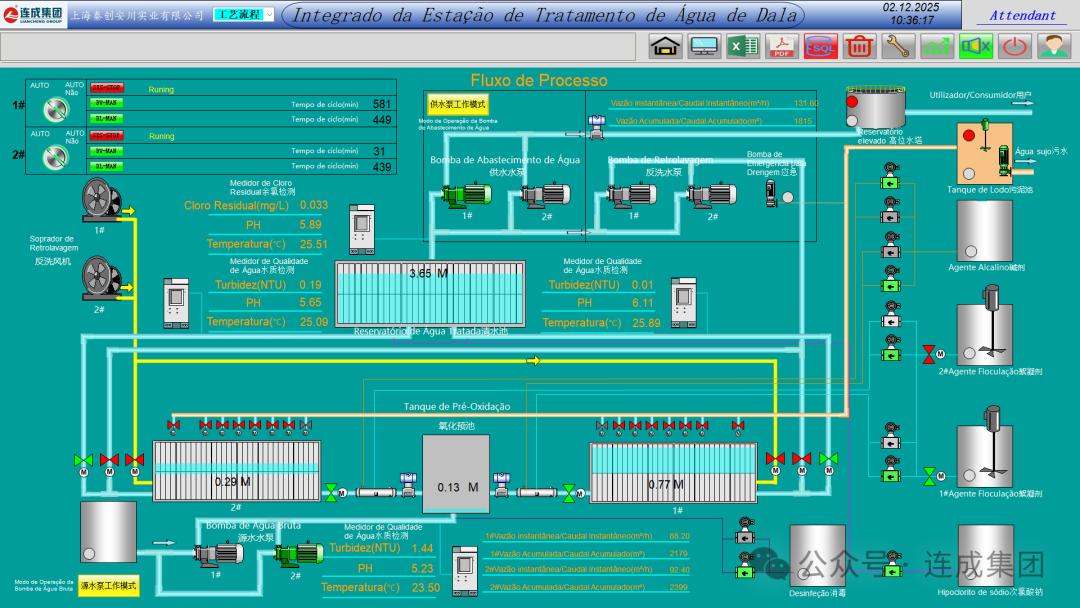

With the rapid development of science and technology, in order to better adapt to market demands, the company has developed the V1.0 version of the intelligent central control system based on the domestic SCADA system architecture. This central control system covers the adaptive sludge discharge unit of the flocculation reaction tank, the control unit of the inclined tube sedimentation system, the constant water level operation control unit, the queuing flushing control unit, the backwashing intelligent control unit, the intelligent dosing control unit, the water quality acquisition unit, and the intelligent (take-out) water supply control unit.

An AI-powered intelligent dosing model was constructed by combining deep learning algorithms. Based on the water quality of the filter bed, the intelligent dosing and pump set optimization were optimized. Historical data of the water plant was collected, and the deep learning AI model was used. After multiple rounds of testing and verification, the model was trained accurately and efficiently, enabling real-time dynamic adjustment and precise AI prediction of dosing. This avoids excessive chemical dosage leading to energy waste and reduces operating costs.

Main functional units of the intelligent central control system:

Adaptive sludge removal unit for flocculation reaction tank

Inclined tube sedimentation system control unit

Constant water level operation control unit

Queue flushing control unit

Backwashing intelligent control unit

Intelligent dosing control unit

Water quality sampling unit

Intelligent water supply control unit

The successful completion of the SPW integrated modular water plant project in Angola marks a significant step forward for Liancheng Group in the overseas water market! Moving forward, we will continue to be driven by technological innovation to contribute to global water security.

Post time: Jan-07-2026