Hubei Zhongte New Chemical Energy Technology Co., Ltd.'s 1.5 million tons/year coking environmental protection upgrading and comprehensive renovation project is located in the Xinye Steel Plant in Huangshi City, Hubei Province. In the second phase, two 60-hole 7-meter reheat top-loading coke ovens and their supporting systems will be newly built, with an annual output of 1.5 million tons of coke. The new construction project includes coke oven body, coal tower, relocation platform, machine side dust removal construction, coke discharge dust removal construction, dust removal construction for coke screening building, dust removal main pipe support and second track of coke blocking car, coke quenching tower, and powder coke precipitation Pools, wet quenching equipment and facilities, coke stations, belt corridors and transfer stations, etc.

The project adopts the latest process package technology of China Metallurgical Coking Engineering Technology Co., Ltd. to achieve the goal of comprehensive transformation of environmental protection upgrades. The new process makes full use of raw coal, improves project integration, reduces process energy consumption, reduces pollution emissions, and improves the core competitiveness of the enterprise market.

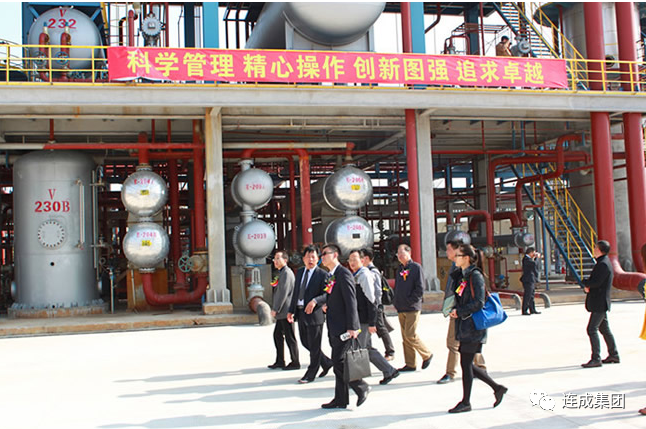

After fierce market competition, Liancheng Group successfully won the bid for Hubei Zhongte New Chemical Energy Technology Co., Ltd. coking unit (3 numbers), chemical production integrated pump room unit (9 numbers) and desulfurization unit (7 numbers) 7m All the water pumps (including fire water pumps) for the top-mounted coke oven, totaling more than 40 sets (6 chemical pumps), have won the bid for nearly 6 million yuan.

The second phase of Hubei Zhongte New Chemical Energy Technology Co., Ltd. is based on the first phase of Zhongte New Chemical Energy, with an additional investment of several billion yuan to build an integrated project with an annual output of 1.5 million tons of coke. The project follows the "Four High Principles" of high-start planning, high-standard configuration, high-quality construction, and high-level operation, and introduces the world's most advanced core technology of the MCC coke resistant process package to create a smart, green, environmentally friendly, low-carbon, A new and intelligent integrated environmental protection upgrade comprehensive demonstration benchmarking project that integrates safety.

As a leading supplier of large-scale customized pumps in China, Liancheng Group's products and services have extensively covered power, water conservancy, steel, metallurgy, petrochemical, municipal and other fields. Thanks to the continuous investment and experience accumulation in the large-scale customized pump market, a complete and mature system has been formed from R&D, design, manufacturing and testing. And with the start of construction and commissioning of the second phase of Zhongte New Chemical Energy Company, the production, assembly, model and real machine testing capabilities of the group and the Dalian plant will be further enhanced by then.

The 1.5 million tons/year coking environmental protection upgrade comprehensive renovation project that won the bid involves multiple models of API610-OH2 series chemical pump products, such as pre-cooling tower circulating water pump (transmission medium: water, a small amount of ammonia), one-tower desulfurization liquid circulation Pump {transmission medium: desulfurization liquid (ammonia, thiocyanate ammonia, catalyst, etc.)}, washing tower waste liquid pump (transportation medium: distilled ammonia wastewater), pickling tower circulating liquid pump (transmission medium: ammonium sulfate mother liquor), alkali The desulfurization liquid (transmission medium: ammonia, ammonia thiocyanide, catalyst, etc.) in the lower section of the scrubber and the upper recirculation liquid pump (transmission medium: dilute alkali solution) of the alkali scrubber demonstrate the company's engineering and technical capabilities in the energy and chemical industry. And product customization capabilities. In the future, the Group and the Dalian factory will increase research on independent innovation technologies and the expansion of digitalization, so as to provide customers with better solutions and win the favor of customers.

Liancheng Group, as a super-large well-known enterprise in the water pump industry in my country, will vigorously promote the spirit of "Water, continuous success is the highest and far-reaching", emphasizing customer value and organizational execution, giving full play to innovative mechanisms, constantly improving itself, and providing customers with With first-class products and high-quality services, we strive to realize Liancheng's ambitious vision of "exploit, forge ahead, and never stop".

Post time: Aug-13-2021