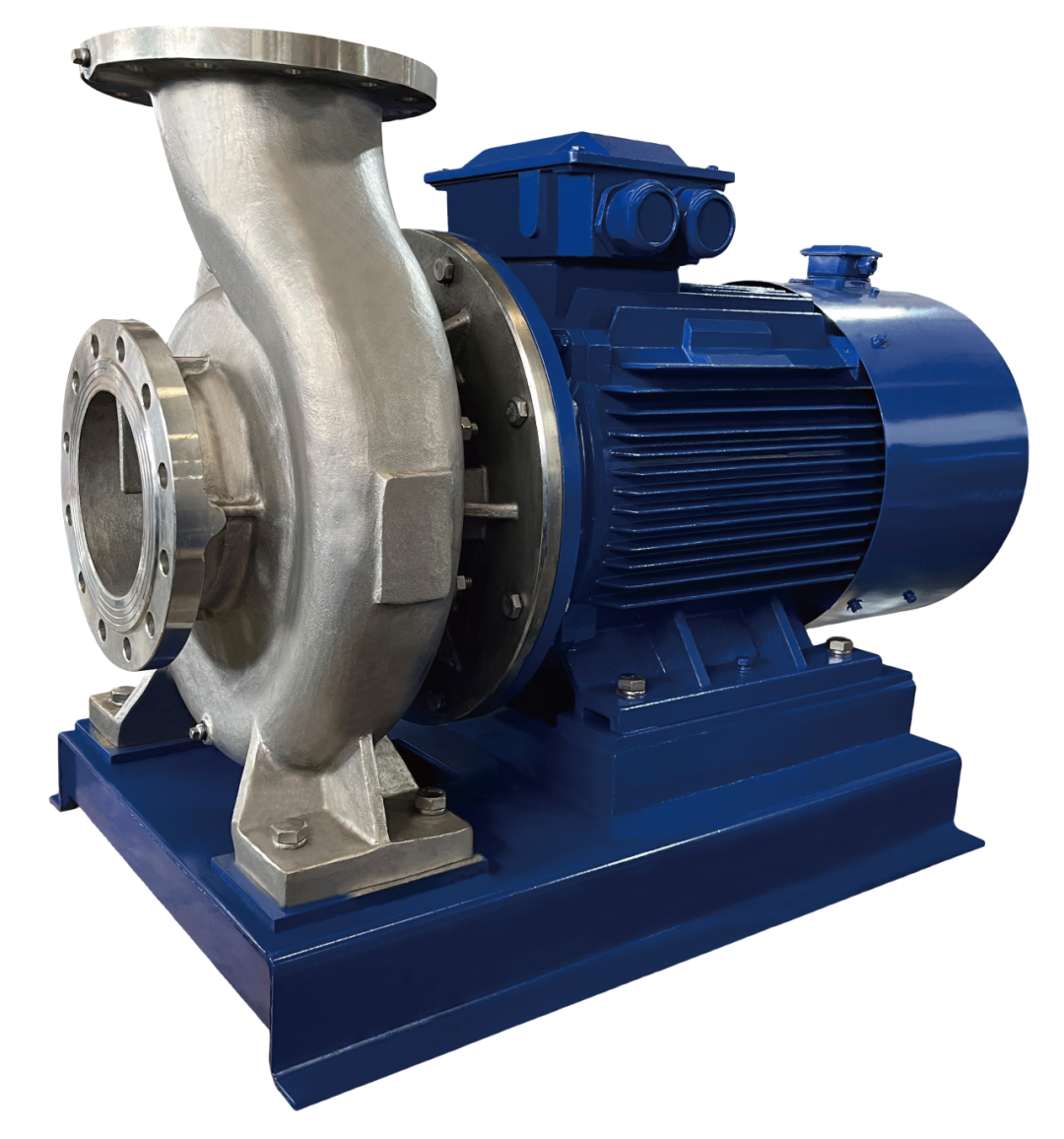

HGL and HGW series single-stage vertical and single-stage horizontal chemical pumps are based on the original chemical pumps of our company. We fully consider the particularity of the structural requirements of chemical pumps during use, draw on advanced structural experience at home and abroad, and adopt separate pumps. shaft, a clamping coupling structure, which has the characteristics of extremely simple structure, high concentricity, small vibration, reliable use, and convenient maintenance. It is a new generation of single-stage chemical pump innovatively developed.

Application

HGL and HGW series chemical pumps can be used to a certain extent in chemical industry, oil transportation, food, beverage, medicine, water treatment, environmental protection and some acids, alkali, salt and other applications according to the specific usage conditions of the user. A medium that is corrosive, contains no solid particles or a small amount of particles, and has a viscosity similar to water. Not recommended for use in toxic, flammable, explosive, or highly corrosive situations.

(1) Nitric acid and applications in nitric acid industry

In the process of producing nitric acid by ammonia oxidation, the dilute nitric acid (50-60%) generated in the stainless steel absorption tower flows out from the bottom of the tower into the stainless steel storage tank, and is transported to the next process with a stainless steel pump. Pay attention to the medium temperature and inlet pressure here.

(2) Applications in phosphoric acid and phosphoric acid industry

For pure acid, Cr13 stainless steel is only resistant to aerated dilute acid, and chromium-nickel (Cr19Ni10) austenitic stainless steel is only resistant to aerated dilute acid. The best phosphoric acid-resistant material is chromium-nickel-molybdenum (ZG07Cr19Ni11Mo2) stainless steel, etc.

However, for the phosphoric acid production process, the material selection of the pump is much more complicated due to the corrosion problems caused by the presence of impurities in the phosphoric acid, and must be treated with caution.

(3) Application in sodium chloride and salt industry (brine water, sea water, etc.)

Chromium-nickel stainless steel has a very low uniform corrosion rate against neutral and slightly alkaline sodium chloride solutions, seawater and salt water at a certain temperature and concentration, and is widely used. However, it should be noted that dangerous localized corrosion may occur in some cases.

Stainless steel pumps are widely used in the food industry for handling brine and salted food. However, attention must be paid to media crystallization issues and mechanical seal selection issues.

(4) Application in sodium hydroxide and alkali industry

Chromium-nickel austenitic stainless steel can withstand sodium hydroxide below 40-50% to about 80°C, but it is not resistant to high-concentration and high-temperature alkali liquid.

Chromium stainless steel is only suitable for low temperature and low concentration alkali solutions.

Attention must be paid to the problem of medium crystallization.

(5) Application in oil transportation

Attention must be paid to the viscosity of the medium, the selection of rubber parts, and whether the motor has explosion-proof requirements, etc.

(6) Application in pharmaceutical industry

Medical pumps can be divided into the following two categories according to the pump's delivery medium:

One type is ordinary water pumps, hot water pumps and wastewater treatment system pumps used in public projects, and the other type is pumps for transporting process media such as chemical liquids, intermediates, pure water, acids and alkalis.

The former has lower requirements for pumps and can be handled by pumps used in general chemical equipment, while the latter has higher requirements for pumps. The pumps must meet the technical requirements for centrifugal pumps used in medical equipment.

(7) Application in food and beverage industry

In the food and beverage industry, the medium is non-corrosive or weakly corrosive, but rust is never allowed, and the purity of the medium is very high. In this case, a stainless steel pump can be used.

Structural features

1. The segmented design of the pump shaft of this series of pumps fundamentally avoids corrosion damage to the motor shaft. This completely ensures the stable and reliable long-term operation of the motor.

2. This series of pumps has a reliable and novel pump shaft structure. The vertical pump can easily use the B5 structure standard motor to directly drive the water pump, and the horizontal pump can easily use the B35 structure standard motor to directly drive the water pump.

3. The pump cover and bracket of this series of pumps are designed as two independent parts with reasonable structure.

4. This series of pumps has a very simple structure and is easy to maintain. Once the pump shaft needs to be replaced, it is easy to disassemble and install, and the positioning is accurate and reliable.

5. The pump shaft and the motor shaft of this series are rigidly connected by a clamped coupling. The advanced and reasonable processing and assembly technology makes the pump shaft have high concentricity, low vibration and low noise.

6. Compared with horizontal chemical pumps of general structure, this series of horizontal pumps has a compact structure and the unit floor space is greatly reduced.

7. This series of pumps adopts excellent hydraulic model design. The performance of the pump is stable and efficient.

8. The pump body, pump cover, impeller and other parts of this series of pumps are precision cast by investment casting, with high dimensional accuracy, smooth flow channels and beautiful appearance.

9. The pump covers, shafts, brackets and other parts of this series of pumps adopt universal designs and are highly interchangeable.

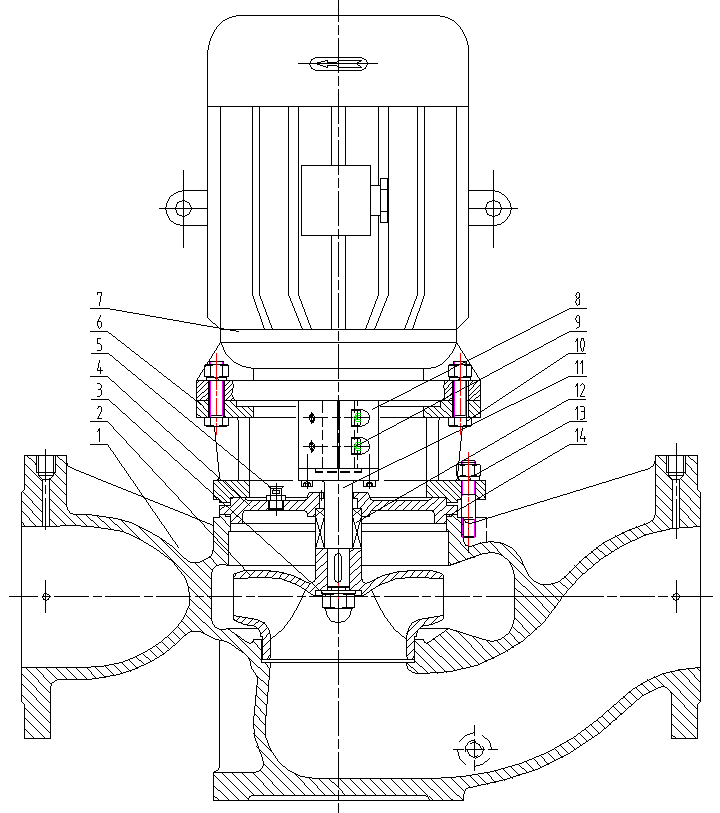

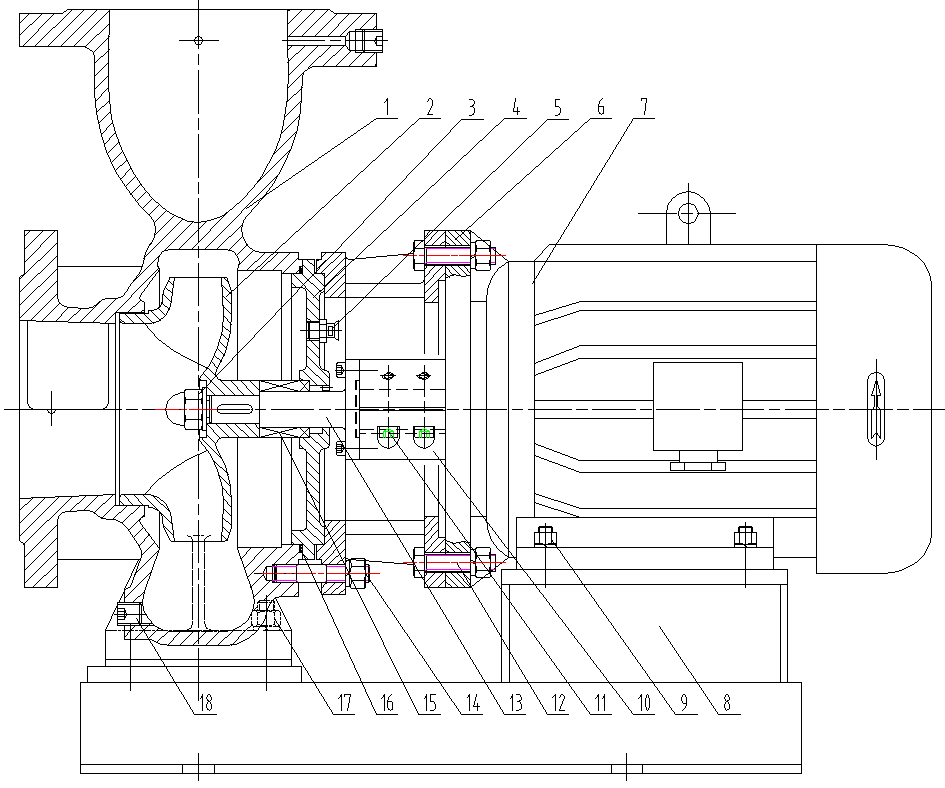

HGL、HGW structure diagram

Post time: Dec-13-2023