In the selection of water pumps, if the selection is improper, the cost may be high or the actual performance of the pump may not meet the needs of the site. Now give an example to illustrate some principles that the water pump needs to follow.

The selection of double suction pump should pay attention to the following points:

1. Speed:

The normal speed is determined according to the customer's given requirements. The lower the speed of the same pump, the corresponding flow rate and lift will decrease. When selecting a model, it is necessary to consider not only the economic performance, but also the site conditions, such as: the viscosity of the medium, wear resistance, self-priming ability, vibration factors, etc.

2. Determination of NPSH:

The NPSH can be determined according to the value given by the customer, or according to the inlet conditions of the pump, medium temperature and on-site atmospheric pressure:

The calculation of the installation height of the water pump (simple algorithm: according to standard atmospheric pressure and normal temperature water) is as follows:

Among them: hg—geometric installation height (positive value is suction up, negative value is reverse flow);

—Atmospheric pressure water head at the installation site (calculated as 10.33m under standard atmospheric pressure and clear water);

hc—suction hydraulic loss; (if the inlet pipeline is short and uncomplicated, it is usually calculated as 0.5m)

—Vaporization pressure head; (clear water at room temperature is calculated as 0.24m)

— Allowable NPSH; (to ensure safety, calculate according to NPSHr×1.2, NPSHr see catalog)

For example, the NPSH NPSHr=4m: Then: hg=10.33-0.5-0.24-(4×1.2)=4.79 m (the settlement result is a positive value, it means that it can suck up to ≤4.79m, that is, the water inlet level can be in the impeller Within 4.79m below the center line; if it is under negative pressure, it must be poured back, and the value of back pouring must be greater than the calculated value, that is, the water inlet level can be above the calculated value above the center line of the impeller).

The above is calculated under the condition of normal temperature, clear water and normal altitude. If the temperature, density and altitude of the medium are abnormal, in order to avoid cavitation and other problems affecting the normal operation of the pump set, the corresponding values should be selected and substituted into the formula for calculation. Among them, the temperature and density of the medium are calculated according to the corresponding values in "Vaporization Pressure and Density of Water at Different Temperatures", and the altitude is calculated according to the corresponding values in "Altitude and Atmospheric Pressure of Major Cities in the Country". Another permissible NPSH is to ensure safety, according to NPSHr×1.4 (this value is at least 1.4).

3. When the inlet pressure of the conventional pump is ≤0.2MPa, when the inlet pressure + head × 1.5 times ≤ the pressure pressure, select according to the conventional material;

Inlet pressure + head × 1.5 times > suppression pressure, the standard materials that meet the requirements should be used; if the inlet pressure is too high or the test pressure is too high, etc. that do not meet the requirements, please confirm with the technology to replace the material or repair the mold and increase the wall thickness;

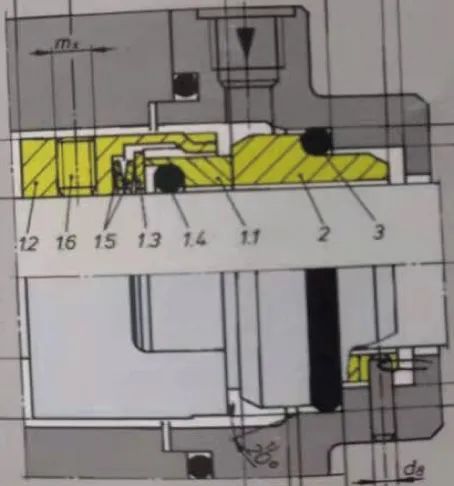

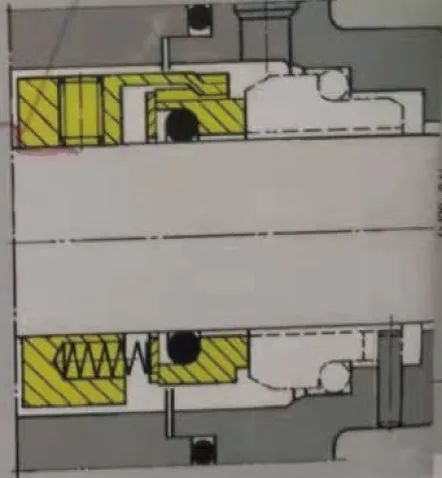

4.Conventional pump mechanical seal models are: M7N, M74 and M37G-G92 series, which one to use depends on the pump design, conventional mechanical seal material: hard/soft (tungsten carbide/graphite); when the inlet pressure is ≥0.8MPa, A balanced mechanical seal must be selected;

5. It is recommended that the medium temperature of the double-suction pump should not exceed 120°C. When 100°C ≤ medium temperature ≤ 120°C, the conventional pump needs to be repaired: the sealing cavity and the bearing part must be equipped with cooling water outside the cooling cavity; all O-rings of the pump are made of Both use: fluorine rubber (including machine seal).

Post time: May-10-2023