1. Before use:

1).Check whether there is oil in the oil chamber.

2). Check whether the plug and sealing gasket on the oil chamber are complete. Check whether the plug has tightened the sealing gasket.

3).Check whether the impeller rotates flexibly.

4). Check whether the power supply device is safe, reliable and normal, check whether the grounding wire in the cable has been reliably grounded, and whether the electric control cabinet has been reliably grounded.

5).Before the pump is put into the pool, it must be inched to check whether the rotation direction is correct. The rotation direction: viewed from the pump inlet, it rotates counterclockwise. If the rotation direction is incorrect, the power supply should be cut off immediately and any two phases of the three-phase cables connected to U, V and W in the electric control cabinet should be replaced.

6).Carefully check whether the pump is deformed or damaged during transportation, storage and installation, and whether the fasteners are loose or fall off.

7).Check whether the cable is damaged or broken, and whether the inlet seal of the cable is in good condition. If it is found that there may be leakage and poor seal, it should be handled properly in time.

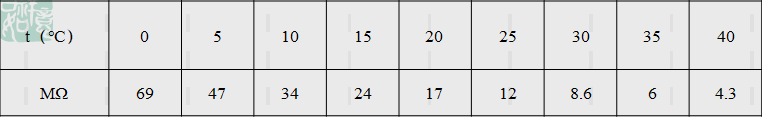

8).Use a 500V megohmmeter to measure the insulation resistance between phases and relative ground of the motor, and its value shall not be lower than that listed in the table below, otherwise the stator winding of the motor shall be dried at a temperature not exceeding 120 C.. Or notify the manufacturer to help.

Relations between minimum cold insulation resistance of winding and ambient temperature are shown in the following table:

2. Starting, running and stopping

1). Starting and running:

When starting, close the flow regulating valve on the discharge pipeline, and then open the valve gradually after the pump runs at full speed.

Do not run for a long time with the discharge valve closed. If there is an inlet valve, the opening or closing of the valve cannot be adjusted when the pump is running.

2). Stop:

Close the flow regulating valve on the discharge pipeline, and then stop. When the temperature is low, the liquid in the pump should be drained to prevent freezing.

3. Repair

1). Regularly check the insulation resistance between phases and relative ground of the motor, and its value shall not be lower than the listed value, otherwise it shall be overhauled, and at the same time, check whether the grounding is firm and reliable.

2). When the maximum clearance between the sealing ring installed on the pump body and the impeller neck in the diameter direction exceeds 2mm, a new sealing ring should be replaced.

3). After the pump runs normally for half a year under the specified working medium conditions, check the condition of the oil chamber. If the oil in the oil chamber is emulsified, replace N10 or N15 mechanical oil in time. The oil in the oil chamber is added to the oil filler to overflow. If the water leakage probe gives an alarm after running for a short time after oil change, the mechanical seal should be overhauled, and if it is damaged, it should be replaced. For pumps used in harsh working conditions, they should be overhauled frequently.

Post time: Jan-29-2024